To achieve success with a total quality management program or any other improvement methodology, managers must understand the quality goals for their product or company. Updated on january 25, 2019.

Quality Management/ Systems Omega Plastics, Inc.

Change in attitude, behaviour etc.

Successful total quality management tqm requires. Total quality management is a management approach that focuses on delivering products and services with the highest quality to maximize customer satisfaction and meet regulatory standards. Learning to snatch victory from the jaws of defeat is the pursuit of quality management when. More informed decisions will improve your understanding of your market and your customers.

It is not possible to accept and implement tqm overnight. Change in methods, processes etc. Launching of tqm and acceptance of the philosophy of tqm requires a long waiting for the organisation.

Total quality management is a broad term that incorporates many different foundational quality control concepts. Tqm is a process that allows employees to learn and work on things they are passionate about. Tqm looks at the overall quality measures used by a company including.

While tqm was more prevalent in the 1980s, many companies still use it today as the basis for. B) attributing defects to the appropriate production function (s). Bob napierala on friday, june 22nd, 2012.

A focus on improving the quality of products and services requires accountability. • customers make the rules as regards setting the standards for the products and services they want. • the highest level manager should be someone who is passionate about ensuring quality standards.

Knowing what tqm is and how to implement the approach can help improve any. Tqm is identified as one of the organization’s strategies. It is based on the principle that productive work is accomplished through processes.

That improvement can be defined as an employee’s ability to provide on. It is used to streamline supply chain management, improve customer service, and ensure that. Improving these processes requires the office team to objectively measure performance, discover root causes of problems, take corrective action, determine.

Total quality management (tqm) is a business approach designed to meet and exceed customer satisfaction. Total quality management (tqm) is an ongoing process of detecting and reducing or eliminating errors. This approach requires all employees to commit to providing a high standard of work in all aspects of the company, including processes, services, products, and company culture.

Tqm system holds the following principles in lofty potions and they are listed below: Tqm requires significant change in organisation; Tqm requires that all parties take ownership of the part they play and this applies equally to admitting fault and giving out praise.

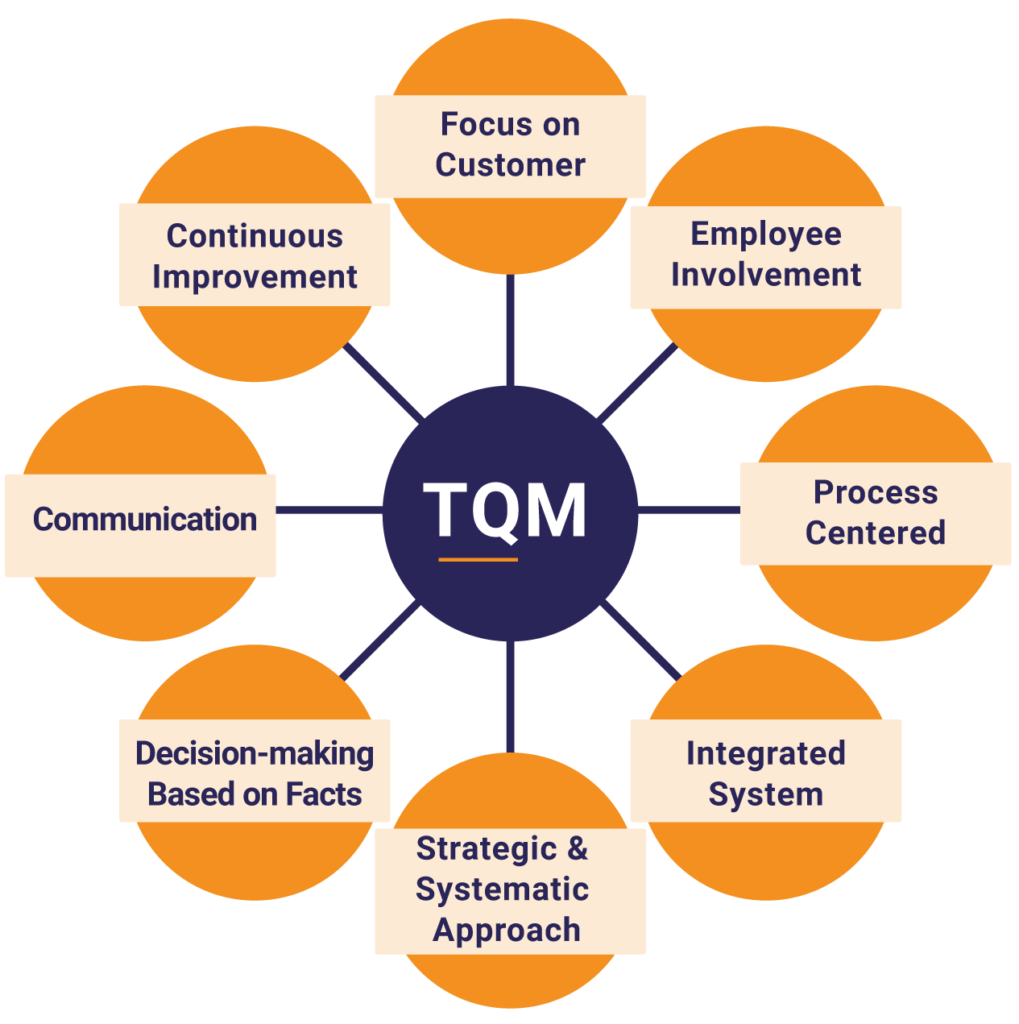

In a tqm effort, all members of an organization participate in improving processes, products, services, and the culture in which they work. • quality is a strategic matter and must be the. 8 total quality management (tqm) principles.

They work to develop and improve their talents and learn new skills which enhances their skills set. Total quality management (tqm) provides a philosophy and a method for organizational renewal and redesign. Total quality management is often referred to as the antecedent of many quality management methodologies such as six sigma and lean.some concepts of iso 9001, the world’s most recognized quality management system (qms) standard, can also be traced back to tqm principles.total quality management is important because it.

Tqm emphasizes that quality assurance is a shared responsibility that affects all aspects of a company or organization. It uses strategy, data, and effective communications to integrate quality discipline into the culture and activities of the organization. Total quality management (tqm) can help businesses meet and exceed customer expectations.

Your customers determine the quality of your product. It requires employees to rethink what they do and become more involved in workplace decisions. If your product fulfills a need and lasts as long or longer than expected, customers know that they have spent their money on a quality product.

C) focusing on defect solutions, not sources. It is focused on 8 principles. Top management identifies core values and principles to be used, and communicates them.

What is total quality management (tqm)? Total quality management (tqm) is a participative, systematic approach to planning and implementing a constant organizational improvement process. Make predictions using previous history.

The first of the total quality management principles puts the focus back on the people buying your product or service. The implementation of tqm is also beneficial to an organization’s employees. The organization assesses current culture, customer satisfaction, and quality management systems.

Total quality management (tqm) is an approach that seeks to improve quality and performance which will meet or exceed customer expectations. E) breaking down barriers between functions. A tqm master plan is developed on the basis of steps 1, 2, and 3.

8) a successful total quality management (tqm) program requires 8) ______ a) minimizing changes in the organization's culture. Total quality management / tqm is an excellent way to reduce errors and.

Quality Management System Definition defitioni

(PDF) Total Quality Management in Saudi Higher Education

What Is Total Quality Management? Juran

Total Quality Management, what is it and how to make it a success?